Design of composite insulators

Composite insulators include many types and which type has its own usage. How to design of composite insulators?

First it should be according to clients’ requirement.

Second according to the insulators will be used for area.

Third according to insulators fuction.

But not all clients know insulators very well, such as Africa, triditional they use porcelain insulators and recent years composite insulators begin to change porcelain insulators, but they are not very familar to composite insulators, so for the factory which should have very experienced engineers to design composite insulators for customers.

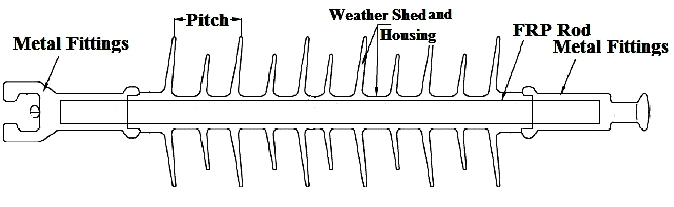

Structure of Composite Insulators

Typically a composite insulator includes fiber glass core rod, end-fitting, and silicone rubber sheds and housing. The core is FRP to burden the tensile load. The reinforcing fiber glass which also called FRP. The end-fitting compressed one core rod and linked with other fittings to hang cable and to link to towers. the material is forged steel, malleable cast iron, aluminum, etc. The silicone rubber sheds and housing provides electrical insulation and protects the FRP.

Picture Composite Insulators

Standards of Composite Insulators

Design composite insulators should reference standards:

IEC 60815 “Guide for the selection of insulators in respect of polluted conditions”.

IEC 61109 “Composite insulators for a.c. overhead lines with a nominal voltage greater than 1000 V: Definitions, test methods and acceptance criteria”.